Luxury women’s winterwear requires far more than beautiful fabrics and good design — it’s a carefully orchestrated process combining craftsmanship, technical precision, and creativity. At The Clothing Manufacturers in London, we work closely with designers to bring premium outerwear collections to life, from first sketch to finished garment. In this article we pull back the curtain to show how a high-end women’s winter coat is made, the key steps, and what distinguishes luxury manufacturing in this category.

1. Concept & Fabric Selection

The journey begins with fabric selection. Winterwear demands high-performance materials that offer warmth, comfort and structure. Unlike lightweight spring pieces, a luxury winter coat must insulate, drape elegantly, retain shape and stand up to wear. Wools, cashmeres and faux furs are favourites for premium feels and insulation. At the same time, technical coatings or laminated fabrics may be used to provide weather resistance without sacrificing style.

Choosing the right fabric is not simply a matter of colour or drape: the manufacturer must evaluate weight, hand-feel, finish, drape, insulation, and how the fabric will behave in your production line. For example, real wool may require certain seam allowances, linings, or under-interfacing to maintain structure. Some mills specialise in luxury woollen textiles and vertical manufacture, giving traceability and quality assurance. Hainsworth+1

In this phase, designers and fabric houses collaborate: swatches are ordered, performance tests (such as pilling, abrasion, colourfastness) may be run, and sample bolts may be produced. For a luxury collection you might also consider fur trims (real or faux), quilted fabrics, or combinations of wool and technical shell fabrics.

2. Pattern Development & Sampling

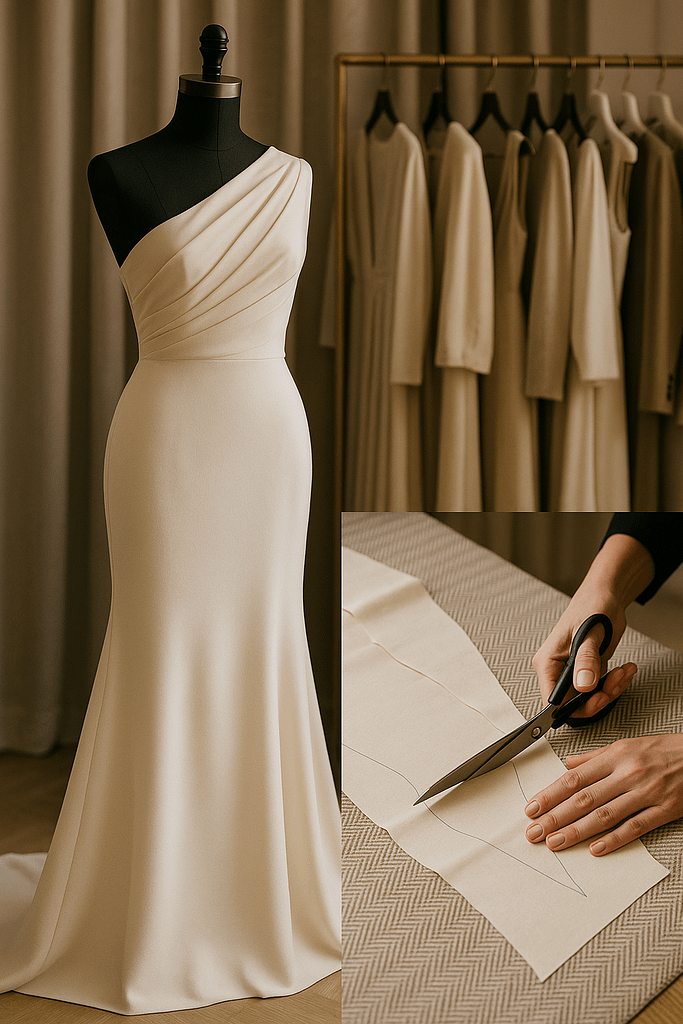

Once the fabric is selected, the next stage is pattern development and sampling. Here the designer’s vision is translated into a functional, perfectly-fitting piece. In luxury outerwear, each pattern must accommodate the weight of the fabric, ensure movement while retaining shape, allow for linings, interfacing and any fur or quilt detailing, and ensure that the finished garment sits and moves beautifully.

Our in-house pattern cutters work from the initial sketch, sometimes collaborating with the designer’s technical pack, to create a toile (mock-up) in muslin or a cheaper fabric. That toile is fitted on a live fit model, adjustments are made, and once approved the fabric companies are notified and sample fabric is cut for the first production sample.

Sampling is about more than fit: you’ll check how interfacing, lining and outer fabric work together; how seams behave under drape; how the coat hangs; and how details (pockets, collars, hems, fur trims) integrate. A structured coat rack full of sample garments in our London studio is a good indicator of this iterative process in action.

3. Production Preparation – Cutting, Marking & Lay-Planning

Having approved the sample, the job moves into production preparation. At this stage, cutting becomes critical. For premium winterwear manufacturing, the number of layers can be extensive: outer fabric, interlining, lining, under-collar pad, pocket bags, facings — each needs precision. Lay-planning (how the pattern pieces are positioned on the fabric) must account for nap, directional trims (fur, quilt lines), fabric width, and yield (to keep costs efficient).

In our London-based manufacturing facility we mark the fabric with chalk or other safe markers, then expertly cut with shears or automatic cutters depending on the run size. Because luxury outerwear uses heavier fabrics, we often allow extra space for seam allowances and press-free allowance. It’s here that structure begins to be built: quality begins with accurate cutting. A tailor cutting wool fabric on a table with shears is a classic hero image for this step.

4. Assembly – Precision, Structure & Finishing

During production, attention to detail is everything: from precision seam alignment to hand-finished hems and linings. This is what really distinguishes a luxury winter coat from a mass-market one.

For example:

- Seam allowances must be consistent, pressed appropriately, and corners turned cleanly (especially on structured coats).

- Interfacings and canvas (if used) must be fused and secured so the coat holds its shape without becoming stiff.

- Lining must be inserted so that movement is comfortable — heavy wool coats can be cumbersome if the lining is too lightweight or slip-less.

- Fur or faux fur trims (on collars, hoods) must be matched in colour, direction and nap — if real fur, the pelts must be sorted, trimmed and stitched carefully.

- Hand-finishing is key: hand-sewn buttons or toggles, hand-stitched pick-stitching, hand-rolled hems or pick-stitched lapels all contribute to the luxury feel. At The Clothing Manufacturers we make sure each stitch reflects the garment’s value.

An example worth noting: long-established British coat maker Mackintosh uses glue and hand-taping of seams for waterproof outerwear, a technique that takes many years to master. Mackintosh

5. Quality Control & Consistency

For brands, investing in expert manufacturing ensures quality and consistency that customers can feel the moment they wear the coat. In luxury outerwear manufacturing, the quality control phase is rigorous. Every finished coat is inspected: outer fabric, lining, trims, stitching, fit, drape, weight, packaging. If the brand is sourcing from the UK or EU, traceability, provenance of materials and sustainability credentials are increasingly important. For example, the Woolmark Company serves as a quality assurance standard for luxury wool products. woolmark.com

Defects in winter outerwear can be costly — imagine a mis-sewn fur trim, uneven quilt lines or a lining that pulls unevenly. The manufacturing partner has to provide process checks, sampling runs and documentation for each batch.

Brands ordering multiple styles (for example your quote: 25 colours × 75 units) will expect consistent fit and quality across runs — meaning the manufacturer must manage colour matching, fabric batches, component sourcing (zips, buttons, fur pieces), and production scheduling with care.

6. Logistics, Packaging & Delivery

Once garments are finished and quality-approved, the next step is logistics. In luxury collections, packaging is part of the experience: garments may be individually dust-bagged, hung on premium hangers, delivered in brand-marked boxes, with swing tags and care instructions printed on high-quality stock. Delivery to showroom or retailer must preserve the garment’s shape and finish (ideally shipped hung and wrapped).

Because winter outerwear tends to be bulky, freight and storage need specialist handling — climate, humidity and handling matter. For a London-based manufacturing partner this means coordinating with freight forwarders, customs (if exporting), and meeting the designer or brand’s lead-times for retail delivery.

7. Why Partnering with a Skilled Manufacturer Matters

For a luxury brand, every element of a winter coat must align: aesthetics, feel, function, fit and finish. Manufacturing is no longer simply a “make it” step — it is a core brand enabler. A skilled manufacturer will:

- Provide early involvement in concept, assisting with fabric selection, pattern advice and prototyping

- Manage sourcing of premium components (e.g., fur trims, heavy-weight linings, engineered interfacings)

- Ensure small batch quality and consistency (helpful when you are quoting 75 units per colour)

- Offer technical expertise (e.g., dealing with bulky wool/fur fabrics, structured shapes, and production planning)

- Offer transparency on lead-time, cost, materials and logistics

- Support revisions and seasonal updates efficiently (for instance, working with your London facility to turn around changes quickly)

By choosing to work closely with experienced manufacturing, a brand ensures that the moment a customer puts on the coat, they feel the difference — the weight of the wool, the smooth lining, the clean collar, the structured shape. That’s what luxury outerwear is about.

8. Sustainability & Future Trends

In the luxury winterwear space, sustainability is increasingly intertwined with craftsmanship. Fabric mills such as Hainsworth in West Yorkshire operate vertical woollen mills and emphasise both heritage and reduced footprint. Hainsworth Others emphasise circular sourcing, dead-stock fabrics and limited editions. For example, the Scottish brand Beira manufactures luxury wool coats from ‘waste’ fabrics sourced from high-end fashion manufacturers. Beira

As your manufacturing facility in London works with high-end clients (such as your winterwear collection for a luxury brand), offering services like small runs, traceability, high-quality finishes and sustainability credentials will position you strongly for luxury outerwear.

9. Final Thoughts

From fabric selection through to final delivery, luxury women’s winterwear manufacturing is an intricate, highly-skilled process. At The Clothing Manufacturers we understand that every detail—material, design, pattern, cut, finish—adds to the story of premium outerwear. For brands investing in winter collections, partnering with a manufacturing facility that appreciates these nuances is not optional—it’s essential.

In short: the next time you see a beautifully-crafted women’s coat on the high street or luxury rack, remember it didn’t just happen. It was meticulously planned, cut on time, sewn with care, hand-finished, inspected and delivered to hold its shape, drape with elegance and feel luxurious from the first wear. That is what sets luxury winterwear apart, and that is what we deliver.