Pattern Cutting Services

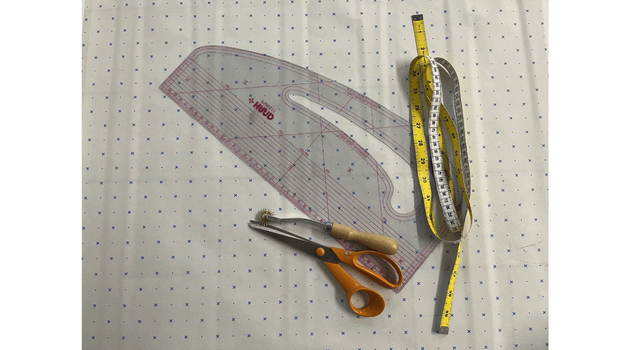

What is Pattern Cutting ?

The process of creating a paper or cardboard template that can be used to create a garment or textile item .

The pattern cutter uses measurements and design specifications to create a pattern that can be used to cut fabric pieces that will be sewn together to create the final product .

This process is a crucial step in the clothing and textile manufacturing process .

PATTERNS MADE

A pattern cutter is responsible for taking design briefs and turning them into physical patterns for garments and textiles .

They must possess creativity, attention to detail, and the ability to work efficiently as part of a team .

They also need to understand the design style and technical requirements of the final product and make sure the patterns reflect those specifications .

What are the Benefits of Pattern Cutting?

Customization

With pattern cutting, it’s possible to create unique designs and styles, so that each garment or textile item produced can be customized to specific needs .

Cost-Effectiveness

By creating accurate patterns, the manufacturing process can be streamlined, reducing the need for additional materials and labor.

High-Quality Control

By creating accurate patterns, pattern cutters can ensure that the final product meets the design specifications, improving the overall quality of the garment or textile item.

Consistency

Pattern cutting ensures that all garments or textile items produced using the same pattern will be the same size and shape, improving the overall consistency .

Enables Mass Production

Pattern cutting allows for the creation of multiple copies of the same pattern, enabling mass production of garments or textile items .

Efficiency

Pattern cutting allows for a more efficient use of fabric, as the pattern cutter can create a template that maximizes the use of fabric and minimizes waste .

Where Do We Do the Pattern Cutting?

Our experienced team of pattern cutters and graders with over 30 years of experience in the field. We do all of the pattern cutting in our studio in London. . To ensure the cut of the garment is to the U.K. spec. We will do a toile in our factory in London to check if the garment is ok before sending the pattern to be sampled in our factories overseas. We then digitize the pattern in house and send it. We use our expertise in all styles of pattern cutting to make sure the pattern is correct and we recommend you try the toile on someone before we then digitize the pattern. This will guarantee the correct fit. That’s why it’s good to have a studio and factory in London so we check before work I started overseas .

How Do We Create Patterns

There are several steps involved in creating patterns for clothing items. The process may vary depending on the specific design and materials being used, but generally includes the following steps:

- Interpret the design brief: The pattern cutter will review the design brief, which includes information on the style, fit, and technical specifications of the final product.

- Create a block pattern: A block pattern is a basic pattern that forms the foundation for the final design. It includes the basic shape and measurements of the garment or textile item.

- Add design elements: Using the block pattern as a starting point, the pattern cutter will add design elements, such as darts, pleats, and seams, to create the final pattern.

- Make adjustments: The pattern cutter will make any necessary adjustments to the pattern to ensure that it meets the design specifications and fits correctly.

- Create a test garment: A test garment is made using the final pattern, it can be used to test the fit and design of the pattern before mass production.

- Finalize the pattern: Once the pattern has been approved, it can be used to create multiple copies for mass production.

- Grading: It is the process of adjusting the pattern to create different sizes and it may be done using software or by hand.

- Marking: It is the process of adding symbols and instructions to the pattern to indicate where to cut, sew and finish the garment.

Creating the final sample, this will be the final product that will be used to check the final product against the original design brief.

Our Services

- Expertise from highly skilled and experienced professional pattern cutters

- Assistance and supervision from a dedicated fashion designer

- Innovative and unique pattern cutting solutions

- Regular pattern inspection as part of our standard service

- Quick turnaround times.

- Special pricing for pattern creation for entire collections

FAQ’s

Related Latest Blogs